Hydraulic oil filters are one of the most important filter elements in any hydraulic system. These elements help keep hydraulic fluid clean and free of contaminants, extending the life of hydraulic components and improving overall system performance.

At the heart of a hydraulic oil filter element is a porous filter material that captures and removes contaminants from the oil as it flows through the system. These materials are designed to handle a wide variety of particle sizes and types, from large debris to fine dust particles. Some of the most common materials used in hydraulic oil filters include cellulose, synthetic fibers, and wire mesh.

A major advantage of hydraulic oil filter elements is their ability to be customized to fit different hydraulic systems and applications. Manufacturers can tailor these elements based on factors such as system flow rate, temperature, and contamination levels. This allows for precise and efficient filtration, maintaining optimum hydraulic system performance.

When selecting hydraulic oil filters, there are several key factors to consider. One is the overall efficiency of the filter, which is measured by its ability to remove particles over a certain size. The other is pressure drop, or the resistance the filter creates within the system. A higher pressure drop indicates that the filter is doing its job, but can also negatively impact system performance and efficiency.

There are two main types of hydraulic oil filters: suction filters and pressure filters. The suction filter is installed in the hydraulic oil tank to filter the oil in the suction system. Pressure filters, on the other hand, are installed in hydraulic lines and filter the oil as it flows through the system. Both types are effective at removing contaminants, but pressure filters are generally considered more efficient and are suitable for high pressure systems.

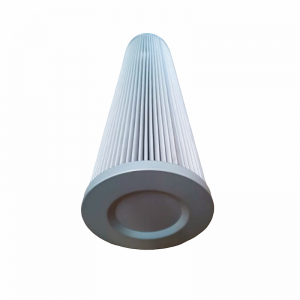

Product features

1)Composite structure with high filtering precision

2)Large dust capacity, long service life

3)Corrosion resistance, pressure resistance

4)Large flowing volume per unit area

5)The filter element is made of stainless steel woven mesh with uniform aperture, high strength and easy to cleaning

6)Alternatives to similar products

Technical specifications

1)Material: Paper, fiberglass and various metals

2)Specifications and sizes are determined according to user requirements