Product features

Filter bags for degas receivers are a critical component in most industrial facilities that require such systems. This type of filter bag plays a vital role in removing impurities, unwanted chemicals and pollutants from the air.

The main purpose of the degassing receiver filter bag is to trap solid and liquid particles that may cause pollution, endanger the environment, or cause equipment failure. This type of filter bag is widely used in degassing receivers to prevent harmful emissions from entering the atmosphere.

In the pharmaceutical industry, filter bags play an important role in promoting safe working conditions for workers. Workers in these industries are exposed to hazardous chemicals that can cause serious health problems over time. Therefore, it is critical to ensure that any equipment that comes into contact with these chemicals is equipped with the necessary safety measures to protect workers.

In the food industry, filter bags are used to remove impurities during production. Food processing requires the use of various chemicals, solvents and other substances that can pollute the air. Therefore, various industries must use filter bags to ensure the safety of consumption in their production process.

Filter bags are common in chemical, oil and gas, and manufacturing for degassing receivers. These industries rely on the use of complex equipment that can release harmful chemicals and impurities into the environment. Therefore, having a reliable filter bag is essential to prevent widespread environmental contamination.

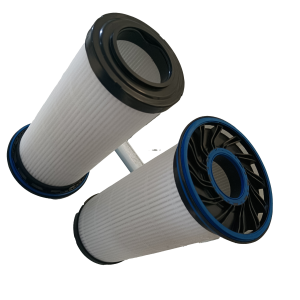

1)Metal filter bag can withstand high temperature above 600 degrees

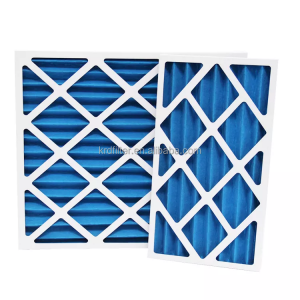

2)Non-woven filter bag has strong pollution capacity, large flow, high pressure resistance;Easy to operate, strong corrosion resistance, good temperature resistance, high rejection rate, low cost, wide application range, acid and alkali resistance, temperature resistance of 150 degrees, non-woven fiber, deep filtration, accuracy range of 0.5 to 600 microns

Technical specifications

Our company can produce various types and materials of high temperature resistant needling cloth bag, anti-static cloth bag, water repellent and oil repellent needling felt, water repellent and oil repellent and easy to clear ash cloth bag, easy to clear ash 208, easy to clear ash 729, etc.Polyester 729, 3232, cloth bag and tube cloth.Glass fiber cloth bags according to guest requirement.And the special-shaped cloth bags made of special materials are acid and alkali resistant

Commonly used specifications:

180*450mm; 180*810mm; 102*209mm; 102*355mm

Or customized according to customer requirements